| Volume LXVIIII No. 2

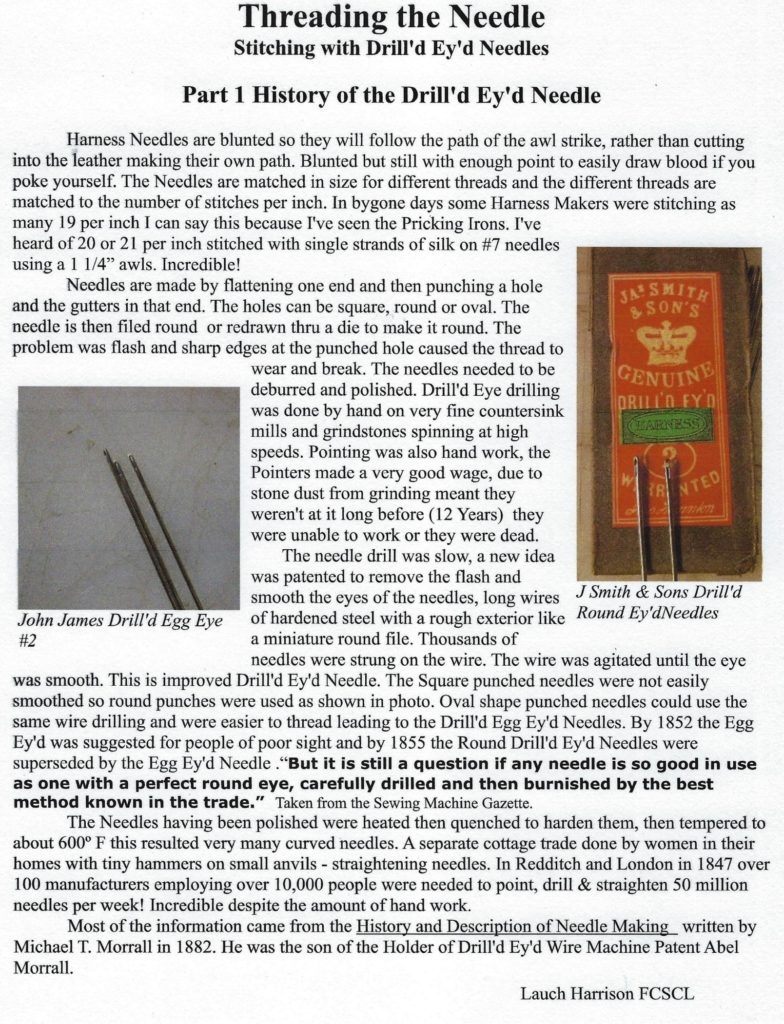

0045-5121 |

|

January, February, March, April – 2021 |

|

Download PDF: Canadian-Leathercrafter-J-F-M-A-2021.pdf  |

|

In this Edition… Page 2 Notes from the Editor, Highlights of the past Executive Mtgs, Membership Info, CSCL Larmour Library |

|

©2021 Canadian Society for Creative Leathercraft All rights reserved. Reproduction in whole or in part without permission of the copyright holder is prohibited. To contact any of our Executive please refer to the CONTACT section of our Website. Website: www.canadianleathercraft.org |

| President: Lauch Harrison 1st Vice-Pres.: Jim Wilkes Past President: Jim Wilkes Treasurer: Della Chynoweth Secretary: Richard Borrow/Lauren Malec |

Membership: Kim Winchester Editor: Barbara Chynoweth ECO: Eugene Pik Privacy Officer: Lauch Harrison Workshops: Lauch Harrison, Jim Wilkes, Lester Pinter |

Note from the Editor….

The Newsletter “Canadian Leathercraft” is your source of information about CSCL and its members. Also check out the CSCL website at www.canadianleathercraft.org and CSCL’s Facebook page. I am always looking for articles for the Newsletter, do you have a project that you have done that you think everyone would be interested in seeing, we are looking for articles?

Highlights from the Past Executive Council Meetings….

Your CSCL Executive have been holding Zoom meetings each month. This year we are going to hold the AGM by Zoom on May 8th from 10 a.m. to Noon. We are also holding a virtual competition for judging entries. See page 3 for the judging requirements.

CSCL Membership

Have you paid your membership? It’s a new Membership Year (April 1 to March 31).

- If you are joining trough a branch pay your CSCL membership to the Branch Treasurer along with your branch membership fee.

- if you are joining as a Member-at-Large or Sustaining Member send your membership payment to the CSCL Treasurer: Della Chynoweth, 3350 Monck Road, Norland, Ontario K0M 2L0 or you can e-transfer to [email protected]. Please be sure to include your contact information.

|

General Member: Individuals interested in leathercraft who belong to one of the CSCL Branches. (Need not be a leathercraft person.) $40.00 plus your Branch membership fee |

General Member – Student*: A registered full-time student shall pay $5.00 |

Member-at-Large: Individual interested in leathercraft who does not belong to one of the CSCL Branches. (Need not be a leathercraft person.) $40.00 |

Sustaining Member: Commercial Organizations interested in supporting the Society. $100.00 or material equivalent to $100.00. |

CSCL Larmour Lending Library

The CSCL lending Library of Books and Patterns can be referenced on our web site www.canadianleathercraft.org. Head to Gallery and click on CSCL Library of Books and Patterns. Under the Patter option there is 80 pages of patterns that may give you ideas of things to make. Under the Book section there is 13 pages of titles of Books and DVD’s about Leather crafting, design and colour. Remember these patterns and books are there for you to borrow from the library. Select item(s) you would like to borrow and send your list to Paul Kitchener at [email protected].

Branch Presidents will assist in pickup and delivery of the orders from branch members.

Members-at-large may order directly from Paul and arrange shipping or printing options, fees may apply.

Memberships are due by March 31st

CSCL LeatherWork Virtual Competition

This was the information sent out the middle of March to all the CSCL Members.

Open To All Members

The Annual General Meeting has been on hold since May 2020, and so has the Judged Competition. The AGM will be held virtually on a ZOOM Conference Call on May 8, 2021 Saturday Morning at 10am. Prior to the Annual, the Competition for Leatherwork will be judged from Photographs. The Council of Fellows set the Criteria for the Competition as follows:

Must be a paid up member (2020-2021) to submit photos.

Articles must not have been in competition prior to entry.

Articles made after May 01, 2019 are eligible.

Photos are to be uploaded to the CSCL Web site prior to April 17, 2021

Maximum of articles/item per Member is 5.

Minimum of 4 photos per item photos, Maximum of 12 photos per item

Photos must be in focus and 5 MP or above 2000 pixel on the longest side. Larger photos are better.

Brief Description and Membership level – General, Associate, or Fellow must accompany photos.

Judging will be anonymous. Judging Committee will not be privy to the Maker.

Zoom Judging Meeting will be on Sunday April 25 at 10am

Prize Category will be set by Judges in attendance at Zoom Meeting.

No Associate, Fellow or Weston Trophy will be Judged.

Photos will be scored by at least 4 Judges

Judge will score each article/item from 0 – 5, scores will be averaged for a percent.

Photos of each article/item should be emailed separately to [email protected]

From there the photos will be uploaded to google albums and made available to all our Members.

This is the first Virtual Judging and the Fellows in the Council would like to see lots of entries from more Members. The Judges will be concerned with the leatherwork, construction, design, and colouring, more than the photos. It is a leatherwork competition not a photo contest.

Yours truly, Lauchlan Harrison FCSCL

Creases & Burnishing on Light Weight Leather

Creasing – 3 – 4 oz light weight leather is not problematic, hot or cold, damp or dry, wood, bone or steel, the leather will crease just as well as heavier stock. The light weight leathers are generally stretchy so heavy pressure can distort the edges.

Here are some things to watch out for:

- When using Natural Veg or light colours a steel burnisher may stain the leather.

- Test a hot tool on some scrap prior to running the crease, you can always darken the line, you can’t remove a burn.

- Lightly passing the tool on the first go can set enough of a line that will prevent a run off. Your dividers can give a good line when set the same.

- Generally Creasing is done prior to beveling the edges, practice on some scrap to see what gives the best burnish.

- Use moderate pressure then increase as needed.

- Creasing is usually the same distance from the edge as stitching – about one thicknesses but there is a choice for every leatherworker.

Beveling – a single piece of lightweight leather is difficult due to stretch and limpness of the edge. The Bevel can be made with a Round Edge Beveler, Edge Shave, or extra small French Edger. The Shave has to be small – 0 or 1. The tool must be sharp and well polished otherwise the tool will “chatter” on the edge and leave raggedness that will not burnish. The best way to polish the inside top of the tool’s groove is to use a piece of thread covered in polishing compound. Tie the thread off at one end and pull the tool along the thread holding you thumb on the string to force it down into the groove. Different thicknesses of thread can be used for the sizes you need. It is best to practice on some scrap to see if the back of the leather requires trimming, beveling the back can make the leather edge to flimsy to burnish.

- Use the Edge shave at low angle to decrease chance of “digging in” and starting the tool chattering

- Round edgers are easier to work with and are forgiving

- If the surface was dampened to get better burnish from the Creaser let the edge dry prior to beveling.

- use a light touch, the bevel is very small and shallow. Pushing down will create concave edge and make it very flimsy.

- Bevel the top only at first.

- Check to see if the back is hairy or ragged it will require trimming.

- Keep the Edge Shave at a low angle and try to take more off the back than the edge.

Burnishing – The real trick is to burnish a single edge of 3 oz leather, better yet crease and burnish the edge. Here are some things to try and watch out for:

- Use Gum and water mixture to help stick down the fibres (Xantham, Guar, Tragacanth)

- Burnish both sides of the leather, keep the leather flat on the table.

- Use a cloth against the edge of the leather with your finger nail.

- Start softly then build up speed and pressure.

- Burnish in one direction can sometimes make a better edge.

- Try not to burnish the top grain past the bevel, don’t burnish the top grain if the crease is to stand out.

Lauch Harrison FCSCL

Using a head Knife?

Tips and Safety Measures

Using a Round Knife or Head Knife is the best way to cut veg tanned leather heavier than 4 oz. The Knife is pushed into the marked pattern lines so you can clearly see where to cut. The Knife can be held up right to make a perpendicular cut or it can be offset at a chosen angle to undercut when needed. The broad area of the blade is used to make long straight cuts, the points can be used on curves. Knife Safety is very important to reduce the chance of injury, here are some tips and rules:

- Never place your free hand in front of the blade

- keep the Knife sharp so you can predict the force needed to cut

- use a cutting surface with “glide” so the surface is not “sticking” the blade.

- Use a strop to remove invisible oxide on the blade prior to use

- strop often when cutting damp Veg as blade will rust inside the veg

- in heavy Veg 10 oz or more trim out the pattern leaving 3/8” excess this allows the Veg to flex out of the way and not trap the blade

- practice on some scrap to gauge the force needed to cut and to check blade’s keenness

- touch up the blade on 800 grit sandpaper then strop if the edge has been rolled or dulled

Cutting Surface for LeatherWork

Things to look for

The Cutting Board is very important to the safe use of the Round Knifes the wrong surface can be dangerous to the user and cause mistakes in cutting. Self healing mats can not be used, you will cut completely through the mat or the soft sticky surface will slow the knife down and make it “jump” ahead. The surface must be hard enough to allow glide but not so hard it will chip or craze. The best cutting surface are smooth plastics Nylon, Teflon & UltraHigh Molecular Weight PolyEthylene the draw back is the cost of these polymers. So the next best thing is High Density PolyEthylene (HDPE) and some of the PolyPropylene (PP) boards.

The best way to test the Board is to run your knife on the board, it should run smoothly and freely without any hitches. The mark left behind should be minimal. This run test gives you the feeling of the downward pressure you should use with your knife. Now when you put the leather in the way it should cut almost as easily, most of the force should be forward not downward. You can Purchase HDPE in different thicknesses, I use 1/2” thick board from P&A Plastics in downtown Hamilton.

Safe Cutting

Cutting Boards of End Grain Hardwood, Aluminum & Glass

Interesting Facts

These materials can be used of cutting boards, as long as the knife does not sink into the surface. Hardwood cutting blocks have been used in butcheries and leather shops of hundreds of years, very heavy and unwieldy, the cutting on the end grain the knife will not follow the path of the grain so it is safer & easier to use. Aluminum can be used it is softer than the steel, knife will require dressing much more often but if just the point is riding on the board the knife will remain sharp. Glass presents a similar but opposite situation the glass is much harder than the steel and will roll the edge, but if just the point is on the glass the knife will cut the leather quite easily. The difficulty with glass is downward pressure can flake the glass and create all sorts of problems.

CSCL 1950 – 2020

|

Broadening the Understanding of Leathercraft It is with profound sadness that the family of Dorothy McPherson, Honorary Life Member, Member-At-Large (MAL), announce her peaceful passing on Wednesday, February 24, 2021 and yet remember her passion for all things creative, especially leathercraft. Former Hamilton (1990) and Woodstock (1997) branches member, Dorothy had opened her home to small, informal meetings to maintain and nurture an interest in leathercrafting for London (2010) leathercrafters. Over the past decades Dorothy successfully competed, retailed and exhibited leather. She founded and was curator of TRC Gallery, London, that staged monthly exhibitions of fine hand art by dozens of skilled Canadian craftsmen including CSCL members. Two of those exhibitions focused solely on leather thus providing a professional CV credit. Dorothy conducted two workshops and served as LEATHER 2010 liaison with Ontario Crafts Council and CANADIAN LEATHERCRAFT Editor/Contributing Writer. A jewellery maker, she co-founded CSCL’s LONDON JEWELLERY AWARD. Dorothy wrote leather biographies for fifty-three CSCL artists for their Ontario Volunteer Service Award proposals. She also successfully acquired for 3 CSCL artists further distinguished awards: Governor General’s Caring Canadian Award, The John Mather Award (OCC), and Queen Elizabeth II Diamond Jubilee Medal. On the ceremony, an MAL (FCSCL) winner shared that Dorothy “has held a special spot in my heart for her belief in me and what I was doing to contribute to both our local and national community.” In 2000, at the September CSCL executive meeting in Cooksville, she and her husband David, were asked to consider producing a newsletter for Members-At-Large as a way to informally chat with, and keep in touch with, members scattered across North America. That launch of a decades-running MAL-designated summer issue of CANADIAN LEATHERCRAFT was instrumental to my young family’s (2006) enthusiastic approach to learning the basics of this time-honoured craft.

An inspiration for talents shared – please feel free to visit the February 2021 Archives online at http://www.westviewfuneralchapel.com Photo of Dorothy’s CSCL Quilt square. Respectfully submitted by Daughter Lauren, CSCL Members-At-Large (MAL) Representative |

Bottom of Form

|

The Canadian Society for Creative Leathercraft CANADIAN LEATHERCRAFT |

|

Volume LXVIIII No. 2 0045-5121 |

|

January, February, March, April – 2021 |

|

|

|

In this Edition… Page 2 Notes from the Editor, Highlights of the past Executive Mtgs, Membership Info, CSCL Larmour Library Page 3 – CSCL LeatherWork Virtual Competition, Creases & Burnishing on Light Weight Leather Page 4 – Using a head Knife? Page 5 – Cutting Surface for LeatherWork. Cutting Boards of End Grain Hardwood, Aluminum & Glass Page 6 – Broadening the Understanding of Leathercraft Page 7 – Projects from the MAL Page 8 & 12 – Threading the Needle |

|

|

©2021 Canadian Society for Creative Leathercraft All rights reserved. Reproduction in whole or in part without permission of the copyright holder is prohibited. To contact any of our Executive please refer to the CONTACT section of our Website. Website: www.canadianleathercraft.org Facebook “Canadian Society for Creative Leathercraft” |

|

|

President: Lauch Harrison 1st Vice-Pres.: Jim Wilkes Past President: Jim Wilkes Treasurer: Della Chynoweth Secretary: Richard Borrow/Lauren Malec |

Membership: Kim Winchester Editor: Barbara Chynoweth ECO ( Electronic Communications Officer): Eugene Pik Privacy Officer: Lauch Harrison Workshops: Lauch Harrison, Jim Wilkes, Lester Pinter |

Note from the Editor….

The Newsletter “Canadian Leathercraft” is your source of information about CSCL and its members. Also check out the CSCL website at www.canadianleathercraft.org and CSCL’s Facebook page. I am always looking for articles for the Newsletter, do you have a project that you have done that you think everyone would be interested in seeing, we are looking for articles?

Highlights from the Past Executive Council Meetings….

Your CSCL Executive have been holding Zoom meetings each month. This year we are going to hold the AGM by Zoom on May 8th from 10 a.m. to Noon. We are also holding a virtual competition for judging entries. See page 3 for the judging requirements.

CSCL Membership

Have you paid your membership? It’s a new Membership Year (April 1 to March 31).

- If you are joining trough a branch pay your CSCL membership to the Branch Treasurer along with your branch membership fee.

- if you are joining as a Member-at-Large or Sustaining Member send your membership payment to the CSCL Treasurer: Della Chynoweth, 3350 Monck Road, Norland, Ontario K0M 2L0 or you can e-transfer to [email protected]. Please be sure to include your contact information.

|

General Member: Individuals interested in leathercraft who belong to one of the CSCL Branches. (Need not be a leathercraft person.) $40.00 plus your Branch membership fee |

General Member – Student*: A registered full-time student shall pay $5.00 |

Member-at-Large: Individual interested in leathercraft who does not belong to one of the CSCL Branches. (Need not be a leathercraft person.) $40.00 |

Sustaining Member: Commercial Organizations interested in supporting the Society. $100.00 or material equivalent to $100.00. |

CSCL Larmour Lending Library

The CSCL lending Library of Books and Patterns can be referenced on our web site www.canadianleathercraft.org. Head to Gallery and click on CSCL Library of Books and Patterns. Under the Patter option there is 80 pages of patterns that may give you ideas of things to make. Under the Book section there is 13 pages of titles of Books and DVD’s about Leather crafting, design and colour. Remember these patterns and books are there for you to borrow from the library. Select item(s) you would like to borrow and send your list to Paul Kitchener at [email protected].

Branch Presidents will assist in pickup and delivery of the orders from branch members.

Members-at-large may order directly from Paul and arrange shipping or printing options, fees may apply.

Memberships are due by March 31st

CSCL LeatherWork Virtual Competition

This was the information sent out the middle of March to all the CSCL Members.

Open To All Members

The Annual General Meeting has been on hold since May 2020, and so has the Judged Competition. The AGM will be held virtually on a ZOOM Conference Call on May 8, 2021 Saturday Morning at 10am. Prior to the Annual, the Competition for Leatherwork will be judged from Photographs. The Council of Fellows set the Criteria for the Competition as follows:

Must be a paid up member (2020-2021) to submit photos.

Articles must not have been in competition prior to entry.

Articles made after May 01, 2019 are eligible.

Photos are to be uploaded to the CSCL Web site prior to April 17, 2021

Maximum of articles/item per Member is 5.

Minimum of 4 photos per item photos, Maximum of 12 photos per item

Photos must be in focus and 5 MP or above 2000 pixel on the longest side. Larger photos are better.

Brief Description and Membership level – General, Associate, or Fellow must accompany photos.

Judging will be anonymous. Judging Committee will not be privy to the Maker.

Zoom Judging Meeting will be on Sunday April 25 at 10am

Prize Category will be set by Judges in attendance at Zoom Meeting.

No Associate, Fellow or Weston Trophy will be Judged.

Photos will be scored by at least 4 Judges

Judge will score each article/item from 0 – 5, scores will be averaged for a percent.

Photos of each article/item should be emailed separately to [email protected]

From there the photos will be uploaded to google albums and made available to all our Members.

This is the first Virtual Judging and the Fellows in the Council would like to see lots of entries from more Members. The Judges will be concerned with the leatherwork, construction, design, and colouring, more than the photos. It is a leatherwork competition not a photo contest.

Yours truly, Lauchlan Harrison FCSCL

Creases & Burnishing on Light Weight Leather

Creasing – 3 – 4 oz light weight leather is not problematic, hot or cold, damp or dry, wood, bone or steel, the leather will crease just as well as heavier stock. The light weight leathers are generally stretchy so heavy pressure can distort the edges.

Here are some things to watch out for:

- When using Natural Veg or light colours a steel burnisher may stain the leather.

- Test a hot tool on some scrap prior to running the crease, you can always darken the line, you can’t remove a burn.

- Lightly passing the tool on the first go can set enough of a line that will prevent a run off. Your dividers can give a good line when set the same.

- Generally Creasing is done prior to beveling the edges, practice on some scrap to see what gives the best burnish.

- Use moderate pressure then increase as needed.

- Creasing is usually the same distance from the edge as stitching – about one thicknesses but there is a choice for every leatherworker.

Beveling – a single piece of lightweight leather is difficult due to stretch and limpness of the edge. The Bevel can be made with a Round Edge Beveler, Edge Shave, or extra small French Edger. The Shave has to be small – 0 or 1. The tool must be sharp and well polished otherwise the tool will “chatter” on the edge and leave raggedness that will not burnish. The best way to polish the inside top of the tool’s groove is to use a piece of thread covered in polishing compound. Tie the thread off at one end and pull the tool along the thread holding you thumb on the string to force it down into the groove. Different thicknesses of thread can be used for the sizes you need. It is best to practice on some scrap to see if the back of the leather requires trimming, beveling the back can make the leather edge to flimsy to burnish.

- Use the Edge shave at low angle to decrease chance of “digging in” and starting the tool chattering

- Round edgers are easier to work with and are forgiving

- If the surface was dampened to get better burnish from the Creaser let the edge dry prior to beveling.

- use a light touch, the bevel is very small and shallow. Pushing down will create concave edge and make it very flimsy.

- Bevel the top only at first.

- Check to see if the back is hairy or ragged it will require trimming.

- Keep the Edge Shave at a low angle and try to take more off the back than the edge.

Burnishing – The real trick is to burnish a single edge of 3 oz leather, better yet crease and burnish the edge. Here are some things to try and watch out for:

- Use Gum and water mixture to help stick down the fibres (Xantham, Guar, Tragacanth)

- Burnish both sides of the leather, keep the leather flat on the table.

- Use a cloth against the edge of the leather with your finger nail.

- Start softly then build up speed and pressure.

- Burnish in one direction can sometimes make a better edge.

- Try not to burnish the top grain past the bevel, don’t burnish the top grain if the crease is to stand out.

Lauch Harrison FCSCL

Using a head Knife?

Tips and Safety Measures

Using a Round Knife or Head Knife is the best way to cut veg tanned leather heavier than 4 oz. The Knife is pushed into the marked pattern lines so you can clearly see where to cut. The Knife can be held up right to make a perpendicular cut or it can be offset at a chosen angle to undercut when needed. The broad area of the blade is used to make long straight cuts, the points can be used on curves. Knife Safety is very important to reduce the chance of injury, here are some tips and rules:

- Never place your free hand in front of the blade

- keep the Knife sharp so you can predict the force needed to cut

- use a cutting surface with “glide” so the surface is not “sticking” the blade.

- Use a strop to remove invisible oxide on the blade prior to use

- strop often when cutting damp Veg as blade will rust inside the veg

- in heavy Veg 10 oz or more trim out the pattern leaving 3/8” excess this allows the Veg to flex out of the way and not trap the blade

- practice on some scrap to gauge the force needed to cut and to check blade’s keenness

- touch up the blade on 800 grit sandpaper then strop if the edge has been rolled or dulled

Cutting Surface for LeatherWork

Things to look for

The Cutting Board is very important to the safe use of the Round Knifes the wrong surface can be dangerous to the user and cause mistakes in cutting. Self healing mats can not be used, you will cut completely through the mat or the soft sticky surface will slow the knife down and make it “jump” ahead. The surface must be hard enough to allow glide but not so hard it will chip or craze. The best cutting surface are smooth plastics Nylon, Teflon & UltraHigh Molecular Weight PolyEthylene the draw back is the cost of these polymers. So the next best thing is High Density PolyEthylene (HDPE) and some of the PolyPropylene (PP) boards.

The best way to test the Board is to run your knife on the board, it should run smoothly and freely without any hitches. The mark left behind should be minimal. This run test gives you the feeling of the downward pressure you should use with your knife. Now when you put the leather in the way it should cut almost as easily, most of the force should be forward not downward. You can Purchase HDPE in different thicknesses, I use 1/2” thick board from P&A Plastics in downtown Hamilton.

Safe Cutting

Cutting Boards of End Grain Hardwood, Aluminum & Glass

Interesting Facts

These materials can be used of cutting boards, as long as the knife does not sink into the surface. Hardwood cutting blocks have been used in butcheries and leather shops of hundreds of years, very heavy and unwieldy, the cutting on the end grain the knife will not follow the path of the grain so it is safer & easier to use. Aluminum can be used it is softer than the steel, knife will require dressing much more often but if just the point is riding on the board the knife will remain sharp. Glass presents a similar but opposite situation the glass is much harder than the steel and will roll the edge, but if just the point is on the glass the knife will cut the leather quite easily. The difficulty with glass is downward pressure can flake the glass and create all sorts of problems.

CSCL 1950 – 2020

|

Broadening the Understanding of Leathercraft It is with profound sadness that the family of Dorothy McPherson, Honorary Life Member, Member-At-Large (MAL), announce her peaceful passing on Wednesday, February 24, 2021 and yet remember her passion for all things creative, especially leathercraft. Former Hamilton (1990) and Woodstock (1997) branches member, Dorothy had opened her home to small, informal meetings to maintain and nurture an interest in leathercrafting for London (2010) leathercrafters. Over the past decades Dorothy successfully competed, retailed and exhibited leather. She founded and was curator of TRC Gallery, London, that staged monthly exhibitions of fine hand art by dozens of skilled Canadian craftsmen including CSCL members. Two of those exhibitions focused solely on leather thus providing a professional CV credit. Dorothy conducted two workshops and served as LEATHER 2010 liaison with Ontario Crafts Council and CANADIAN LEATHERCRAFT Editor/Contributing Writer. A jewellery maker, she co-founded CSCL’s LONDON JEWELLERY AWARD. Dorothy wrote leather biographies for fifty-three CSCL artists for their Ontario Volunteer Service Award proposals. She also successfully acquired for 3 CSCL artists further distinguished awards: Governor General’s Caring Canadian Award, The John Mather Award (OCC), and Queen Elizabeth II Diamond Jubilee Medal. On the ceremony, an MAL (FCSCL) winner shared that Dorothy “has held a special spot in my heart for her belief in me and what I was doing to contribute to both our local and national community.” In 2000, at the September CSCL executive meeting in Cooksville, she and her husband David, were asked to consider producing a newsletter for Members-At-Large as a way to informally chat with, and keep in touch with, members scattered across North America. That launch of a decades-running MAL-designated summer issue of CANADIAN LEATHERCRAFT was instrumental to my young family’s (2006) enthusiastic approach to learning the basics of this time-honoured craft.

An inspiration for talents shared – please feel free to visit the February 2021 Archives online at http://www.westviewfuneralchapel.com Photo of Dorothy’s CSCL Quilt square. Respectfully submitted by Daughter Lauren, CSCL Members-At-Large (MAL) Representative |

Bottom of Form

Dorothy retired in 2013, further dedicated to supporting the arts, World Vision, MFPA Canada, neighbours, family and friends. She will be greatly missed.

Dorothy retired in 2013, further dedicated to supporting the arts, World Vision, MFPA Canada, neighbours, family and friends. She will be greatly missed.

Dorothy retired in 2013, further dedicated to supporting the arts, World Vision, MFPA Canada, neighbours, family and friends. She will be greatly missed.

Dorothy retired in 2013, further dedicated to supporting the arts, World Vision, MFPA Canada, neighbours, family and friends. She will be greatly missed.