| The Canadian Society for Creative Leathercraft

CANADIAN LEATHERCRAFT Download PDF here: https://canadianleathercraft.org/wp-content/uploads/2020/11/Canadian-Leathercrafter-Summer-2020.pdf |

| Volume LXVIII No. 4

0045-5121 |

|

Summer – 2020 |

|

| In this Edition…

Page 2 Notes from the Editor, Highlights of the past Executive Mtgs, Membership Info, CSCL Larmour Library Page 3 – 9 Hinged Box with Lauch Harrison Page 9 – Last issue there was a pattern for baby moccasins and here is a pattern for beading the Vamps. |

|

| ©2020 Canadian Society for Creative Leathercraft All rights reserved. Reproduction in whole or in part without permission of the copyright holder is prohibited.

To contact any of our Executive please refer to the CONTACT section of our Website. Website: www.canadianleathercraft.org Facebook “Canadian Society for Creative Leathercraft” |

|

| President: Lauch Harrison 1st Vice-Pres.: Jim Wilkes Past President: Jim Wilkes Treasurer: Della Chynoweth Secretary: Richard Borrow |

Membership: Kim Winchester Editor: Barbara Chynoweth ECO: Eugene Pik Privacy Officer: Lauch Harrison Workshops:Lauch Harrison, Jim Wilkes, Lester Pinter |

Note from the Editor….

Because all our meetings and workshops have been put on hold, the Workshop Committee decided to do the box workshop in our Newsletter.

The Quarterly Newsletter “Canadian Leathercraft” is your source of information about CSCL and its members. Also check out the CSCL website at www.canadianleathercraft.org and CSCL’s Facebook page.

Highlights from the Past Executive Council Meetings….

The Executive have been meeting by Zoom. The Branches have been keeping in touch with their members but not much activity has been happening do to COVID. We still are unable to set a date for the Annual Meeting as everything is still uncertain.

CSCL Larmour Lending Library

The CSCL lending Library of Books and Patterns can be referenced on our web site www.canadianleathercraft.org. Head to Gallery and click on CSCL Library of Books and Patterns. Under the Patter option there is 80 pages of patterns that may give you ideas of things to make. Under the Book section there is 13 pages of titles of Books and DVD’s about Leather crafting, design and colour. Remember these patterns and books are there for you to borrow from the library. Select item(s) you would like to borrow and send your list to Paul Kitchener at [email protected].

Branch Presidents will assist in pickup and delivery of the orders from branch members.

Members-at-large may order directly from Paul and arrange shipping or printing options, fees may apply.

Memberships are due by March 31st

Hinged Box with Lauch Harrison

Outline

This box will use 5/6oz Veg Leather & 8oz Sole Leather to construct an interlocking hinged top that will cover a small leather box. Alcohol Dye will be used to colour the veg tan leather: block dye & saturation will be used. The Hinged Box design was created by David Trotter and perfected by David McPherson FCSCL, this iteration is a combination of what I could remember and what I reinvented to for the Hinged Box Project.

This box will use 5/6oz Veg Leather & 8oz Sole Leather to construct an interlocking hinged top that will cover a small leather box. Alcohol Dye will be used to colour the veg tan leather: block dye & saturation will be used. The Hinged Box design was created by David Trotter and perfected by David McPherson FCSCL, this iteration is a combination of what I could remember and what I reinvented to for the Hinged Box Project.

Material

-

- Sq Ft of 5/6 oz Veg Leather, 6” x 4” piece 8 oz sole leather, 3/8” wood dowel 7” , dye, burnish gum, Contact Adhesive, White Glue

Tools

Head Knife or scalpel, X-acto or Exel #18 Flat Chisel in chucked Handle, Straight Edge, Small Round Edger #0 & #1, cutting boards, scratch awl, bone folder, spring clamps, Clamping Boards, Smooth Faced Hammer, French Edgers and Carving tools.

Round point Awl, Straight Edges, Set Squares, Rulers, Round/Head Knives or well sharpened/polished knives will be able to cut skirting or other heavy leather without undue strain on the hands. Dye and Gum Tragacath, Rampart Round Edger #1, CSO French Edger #0 , CSO Carving tool 1/8” and 3/32”, Excel #18 flat Chisel replacement blade in a chucked handle, Shoe Anvil and Smooth Faced Hammer, Bone Folder, Clamps and glue up boards – Paint stir sticks, Sandpaper, mandrels and blocks. As seen below in photo

The Skills

This is an advanced project. Craftsman should know techniques for: cutting and trimming heavy leather with a Round/Head Knife Safely, Edge rounding and burnishing, Dyeing methods- Block Dye, Saturation Dye, Gouging & Skiving, and Glue ups.

The Pattern and Material

The box can be made entirely of 5/6oz veg tanned leather using a double layer for the base. Using sole leather for the base and if desired a top piece will add rigidity and needed weight. The lay out will be done on a rectangle of leather 20” x 11”. Three pieces; the side, lower hinge and hinged top will be traced and cut. The sole leather base will be precut to save time. If you use 5oz leather the bottom is made from two pieces. Full size patterns of the hinge are at the back of the booklet.

Decoration and Design

The box will be dyed. Molding and creasing work can be incorporated onto the top and sides of the box.

The first dye will be a saturation dye of Saddle Tan, then block dye with Mahogany. Participants are encouraged to use their own favourite colours.

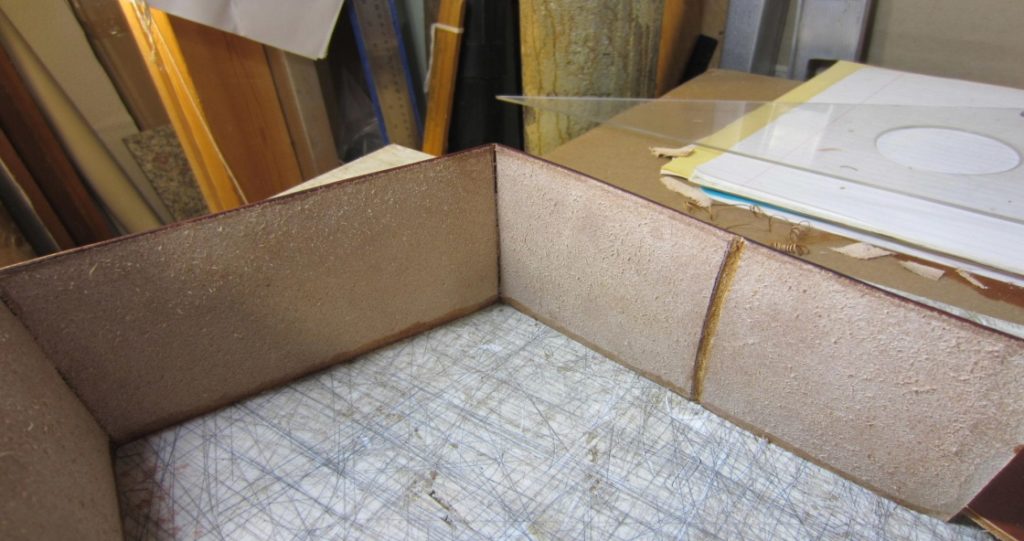

Glue up

White glue will be used on the Top Hinge piece, this allows reposition without distorting the leather. The lid has to be flat and regular. The sides and bottom are attached using contact adhesive, the grain side of the leather has to be well scratched and roughed up to get a good glue bond especially near the hinge dowel. Contact adhesive is only ready to bond when both sides are dry enough that no adhesive transfers when touched with a finger. A shoe anvil and smoothed faced hammer will be used to get a firm bond.

Trimming

The lid gets trimmed if the glue up is off kilter, using pattern lines and a knife. A spoke shave or coarse sandpaper can be used to smooth the edge of the top if needed. A corner rounder will be used to finish the corners, if you wish you can hand trim the corners or leave them square. The edges of the top will be very slightly beveled with a #0 or #1 this will leave a flatter edge. This flatter edge will be sanded and burnished.

The Project

Layout and trace the pattern on the grain, the leather will be slightly dampened to achieve visible marks. Proceed to dye and decorate the entire piece of leather and, this will give an even smooth transition between the pieces. The use of block dyeing will show the pattern. Cut out the edges of the pieces.

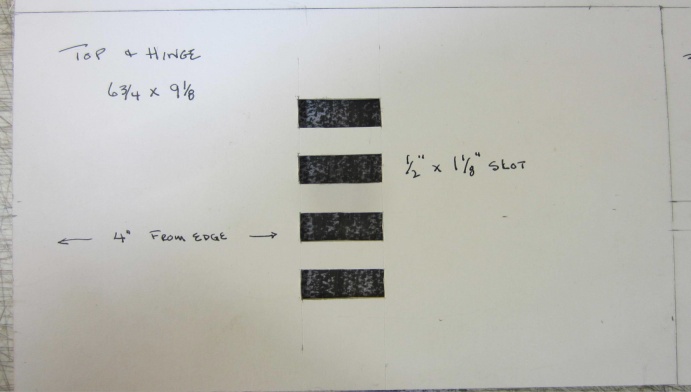

Top and Hinge

Make the top Hinge pattern out of card stock, cut out the slots. Position the pattern on the leather and trace the slots with a scratch awl. Cut the short edges of the slots on the top hinge using a 1/2” chisel blade – angle the blade back at 30º so that the grain side sticks out farther than the back. Use the 30º guide for accuracy. Cut the long edge of the slot with head knife or scalpel. Make sure to under cut to get all the “hairy pieces” out of the slot.

Round the edges of slots on the back side/flesh side only using a #1 round edger.

Round or Bevel the grain on the main edges of the top only using a #0 edger.

Dye the edge of the top

Burnish the slots using the wood dowel and some gum trag.

Draw a glue up lines on the flesh side along the short edge to the slots to the edge of the leather.

Damped the hinge and fold over the dowel to get some memory of the fold.

Paint on the white glue getting the up close to the glue lines.

Fold the top and position in the glue clamps.

Clamp for 10 minutes then remove from clamp and place the dowel in the hinge.

Push down near the hinge with a bone folder to flatten the top and tighten the hinge.

Side

Bevel or round the top and bottom edges of the grain side with #0 edger.

Position the bottom piece with it’s long side parallel to the side piece – and it’s right hand edge 13 1/2” in from the side’s edge. Trace down the both short sides of the base.

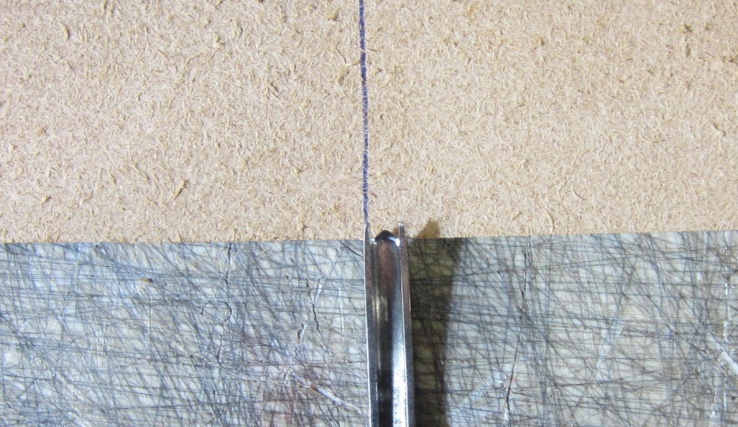

Using a Gouge or Carving tool run a gouge or channel down the right hand side on the right hand side of the line using a square or straight edge.

Gouge the channel on the left hand side on the left line using a square or straight edge.

Spin the base 90º and place on the outside edge of the Gouge.

Trace down the side of the base. Do both sides and gouge outside the lines on both sides.

Bevel or round the top edge of the flesh side using #1 edger.

Skive the two short sides on the flesh side only. Make the skive about 1” wide.

Scratch the grain side skived edge overlap on the right hand end.

Dye and burnish the top edge.

Dampen and fold the gouged corners, to give them some memory.

Open the corners up and apply contact adhesive.

Apply Contact Adhesive Glue on the flesh side bottom edge of the side and on the edge of the sole leather. Apply Contact adhesive to the overlaping skives.

Squeeze the middle two gouges make the corners sharp all the way up and down.

Attach the front of side to the bottom plate, keeping the bottom plate flat on the table. Start at the front of the box, fitting the two corners evenly on both sides then flatten out any bumps.

Squeeze the corner on the right end, the one that has been skived, scratched and glued.

Attach the corner to the bottom plate, Start at the front of the box, fitting the corner evenly.

Squeeze the last corner.

Attach the last corner to the bottom plate, Start at the front of the box, fitting the corner evenly. Press the overlap together.

Check for fit on the bottom, if it looks good tap glue joints with a hammer.

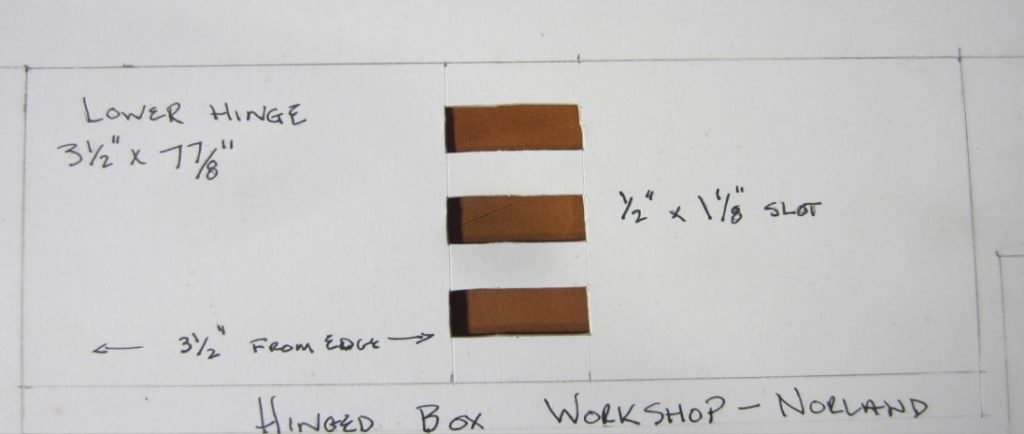

Lower Hinge

Cut the short edges of the slots on the lower hinge using a 1/2” chisel blade – angle the blade straight up and down. Cut the long edge of the slot with head knife or scalpel. Make sure to under cut to get all the “hairy pieces” out of the slot.

Round the edges of slots on the back side/flesh side only using a #1 round edger.

Round or Bevel the grain long outside edges top only using a #0 edger.

Dye the edge of the lower hinge and burnish with gum.

Dye the short edges of the slot.

Burnish the slots using the wood dowel and some gum trag.

Fit the hinges together and work it back and forth til it get smoother. Keep at it til the joints start to work. The two hinges are the same size and to fit both of them have to give a little. Ensure measurements are correct, wiggle and move the hinge to compact and burnish the leather. This can be a trying experience as the leather may be damp and un cooperative.

Extend a glue line on the flesh side along the short edge to the slots to the edge of the leather.

Damped the hinge and fold over the dowel to get some memory of the fold.

Mark the side with 3 1/2” distance to the edge with pen on the grain

Centre the hinge on the back of the box over the joint. With the longer 3 1/2” facing out.

Mark the edge of the hinge lightly with a scratch awl.

Scratch & Scuff the grain of the side with sand paper or knife. Top and bottom edges are key.

Apply Contact Adhesive glue on the flesh side of the hinge making sure to get the adhesive right up to the lines.

Apply Contact Adhesive glue to the grain side of the box.

Assemble the hinge with the 3 1/2” side out, making sure the slots are even with the top of the box, and the lower edge is even with the bottom.

Fold the hinge over and settle it on the bottom plate mark the sides, then lift the hinge.

Apply Contact Adhesive to the marked lines and to the bottom hinge piece

Glue the bottom hinge together flesh to flesh.

Tap with a hammer if the hinge is right.

Apply gum trag and burnish the inside edges of the hinge

Top Hinge after the glue has cured or dried

Trim and sand the edges. Use the coarse sandpaper in one direction only. Use finer sandpaper to get the edge nice and flat.

Round the edge if needed with #0 edger.

Dye the edges.

Apply gum trag and burnish the edge.

Apply gum trag to the hinge and burnish the slots with the dowel.

Fit the hinges together and work it back and forth til it get smoother. Keep at it til the joints start to work. Do not remove any more leather from the hinge slots.

Top Hinge Lid Alignment Spacer if required

Cut two pieces of 5oz leather or one piece of sole leather in the same pattern as the bottom.

Glue the two pieces of leather together flesh to flesh.

Colour or Dye the leather.

Cut 1/8 of an inch off one of the long edges and round the corners.

Trim, sand and smooth the other edges

Round Bevel the top edges of the Dyed side with #0 or #1 Beveller

Dye the edges

Burnish the edges with gum trag

Fit spacing piece for hinged top, Use double sided tape to get a good fit.

Mark the position with an awl.

Scratch and scuff the area on the Top Hing Lid and the back of the alignment spacer.

Assemble the spacer with contact adhesive making sure it is tapped down securely.

Moisten the box and Rub it down with a coarse cloth to burnish and smooth the leather.

Spray with Super Sheen, Lacquer or your favorite finish

brought to you by,

Lauch Harrison, ACSCL

| Last issue there was a pattern for baby moccasins and here is a pattern for beading the Vamps. | |

Markings on the inside of the Vamp for beading |

Outside of the Vamp with the bead work completed |